Woodworking Machinery

MBQ630A Four Side Moulder

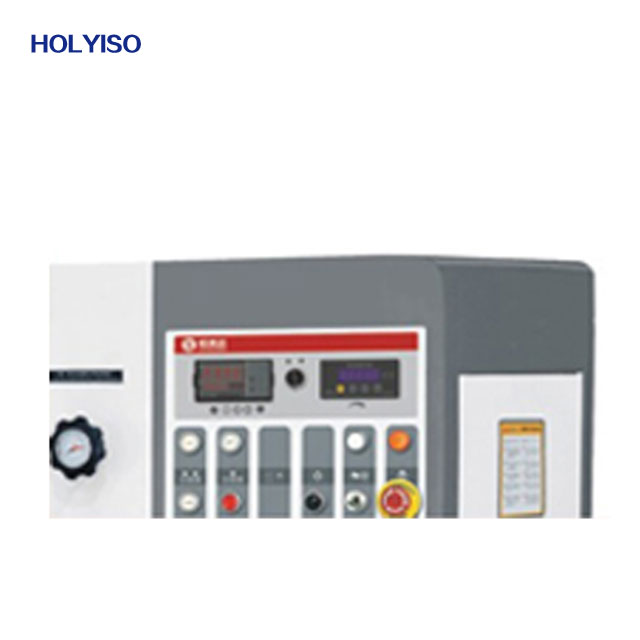

MBQ630A Four Side Moulder Specifications:ModelMBQ630AMax.working width300mmMin.working width25m

MBQ630A Four Side Moulder

Specifications:

Model | MBQ630A |

Max.working width | 300mm |

Min.working width | 25mm |

Max.working thickness | 200mm |

Min.working thinkness | 8mm |

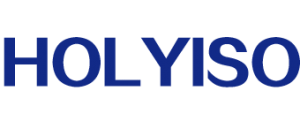

Spindle amounts | 6 pcs |

Spindle speed | 6000rpn |

Feed speed | 6-35m/min |

Spindle diameter | φ40mm |

Cutter diameter First bottom cutter | φ125 |

Right vertical cutter | φ125-φ200 |

Left vertical cutter | φ125-φ200 |

First top cutter | φ125-φ200 |

Second top cutter | φ125-φ200 |

Second bottom spindle | φ125-φ200 |

Motor power First bottom cutter | 15kw/20hp |

Right vertical cutter | 11kw/15hp |

Left vertical cutter | 11kw/15hp |

Fist top cutter | 15kw/20hp |

Second top cutter | 15kw/20hp |

Second bottom cutter | 15kw/20hp |

Feed motor | 7.5kw/10hp |

Beam elevation | 0.75kw/1hp |

Total power | 90.25kw/121hp |

Feeding wheel Dia. | 140*35*50 |

Suction hood Dia. | φ140 |

Overall dimensions | 4560*1725*1735mm |

Packing dimensions | 4760x1929x1835mm |

Weight | 5100kg |

Details:

Outstanding Characteristic:

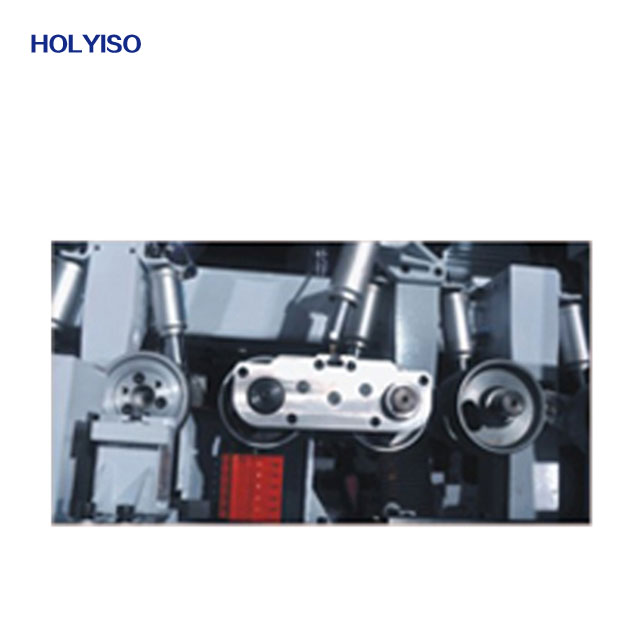

1.This adopts frequency conversion material feeding,material feeding speed ranges from 6-35m/min.

2.Each main shaft is driven by independent electric motor,cutting force is powerful.

3.Main shaft is adjustable to focus on the front,operation is convenient.

4.Hard chrome plating worktable is durable.

5.Equips with auxiliary unit alarming lack of material,it effectively improves smooth feed-in while lack of material.

6.Multi-group drive rollers improve feeding efficiency.

7.Adopts central charging system ,features convenience and promptness.

8.International brands electrical parts are applied for good stability.

9.On the horizontal axis with the front support means to improve the rigidity of the spindle.

10.Spare parts are thick and solid to maintain high precision,high stability and high reliability.

11.Pneumatic compressed feeding roller is applied ,the pressing force can be adjusted by stages which is favorable for smooth feeding of timbers with different thickness.

12.Completely sealed safety shield can avoid flying of saw dust and isolate noise efficiently and protect operators.