Woodworking Machinery

MBQ723UA Four-side moulder

Machine Frame:

Main Parts:

Specification:

Model | MBQ723UA |

Max.working width | 230mm |

Min.working width | 25mm |

Max.working thickness | 150mm |

Min.working thinkness | 8mm |

Spindle amounts | 7pcs |

Spindle speed | 6000rpn |

Feed speed | 6-30m/min |

Spindle diameter | φ40mm |

Cutter diameter First bottom cutter | φ125 |

Right vertical cutter | φ125-φ200 |

Left vertical cutter | φ125-φ200 |

First top cutter | φ125-φ200 |

Second top cutter | φ125-φ200 |

Second bottom spindle | φ125-φ200 |

Universal spindle | Φ160 |

Motor power First bottom cutter | 7.5kw/10hp |

Right vertical cutter | 7.5kw/10hp |

Left vertical cutter | 7.5kw/10hp |

Fist top cutter | 11kw/15hp |

Universal spindle | 4.5kw/5.5hp |

Second top cutter | 7.5kw/10hp |

Second bottom cutter | 7.5kw/10hp |

Feed motor | 5.5kw/7.5hp |

Beam elevation | 0.75kw/1hp |

Total power | 58.75kw/78.5hp |

Feeding wheel Dia. | 140*35*50 |

Suction hood Dia. | φ140 |

Overall dimensions | 4560*1725*1735mm |

Packing dimensions | 4760x1929x1835mm |

Weight | 4630kg |

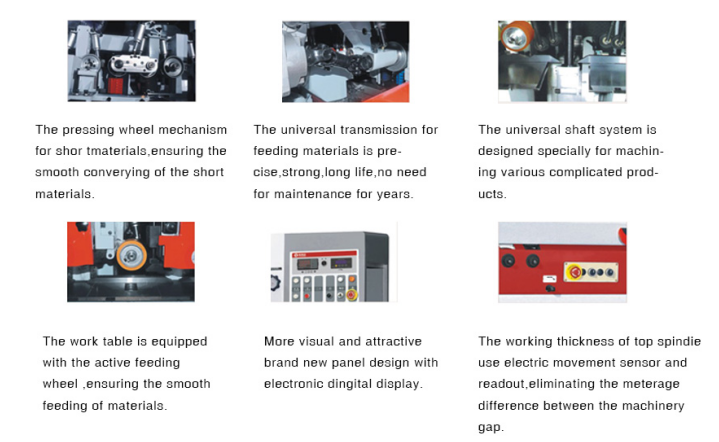

Outstanding Characteristic:

1.Step-less feeding system,speed ranges from 6-30m/min

2.Independent motor drive each main spindle and makes stronger cutting force

3.One concentrate adjustment control panel in front of machine to make operation easy

4.Hard chromed working table with perfect performance of wear resistance

5.Bottom driving roller on the working table makes feeding easy

6.Centralized lubrication system,make for easy operating

7.Fit on qualified brand electrical element with stability performance

8.Top spindle equipped with support device to promote hardness performance of main top spindles

9.With full protection safety hood to avoid saw dust flying and noise ,and offer safety protection of operator .

10.Air cylinder controlled hold-down feed rollers,to be adjusted subsections and make for unblocked feeding when processing wood pieces with different thickness.

11.With short feeding device to promote performance of unblocked feeding of short pieces.